Our companies

We have extensive experience in machining, we provide drilling, milling and turning. Modern machinery in the hands of our experienced staff allows us to work on orders of different materials, complex shapes and sizes. In addition, we offer sophisticated development and assembly of custom-made single-purpose equipment for a variety of industries.

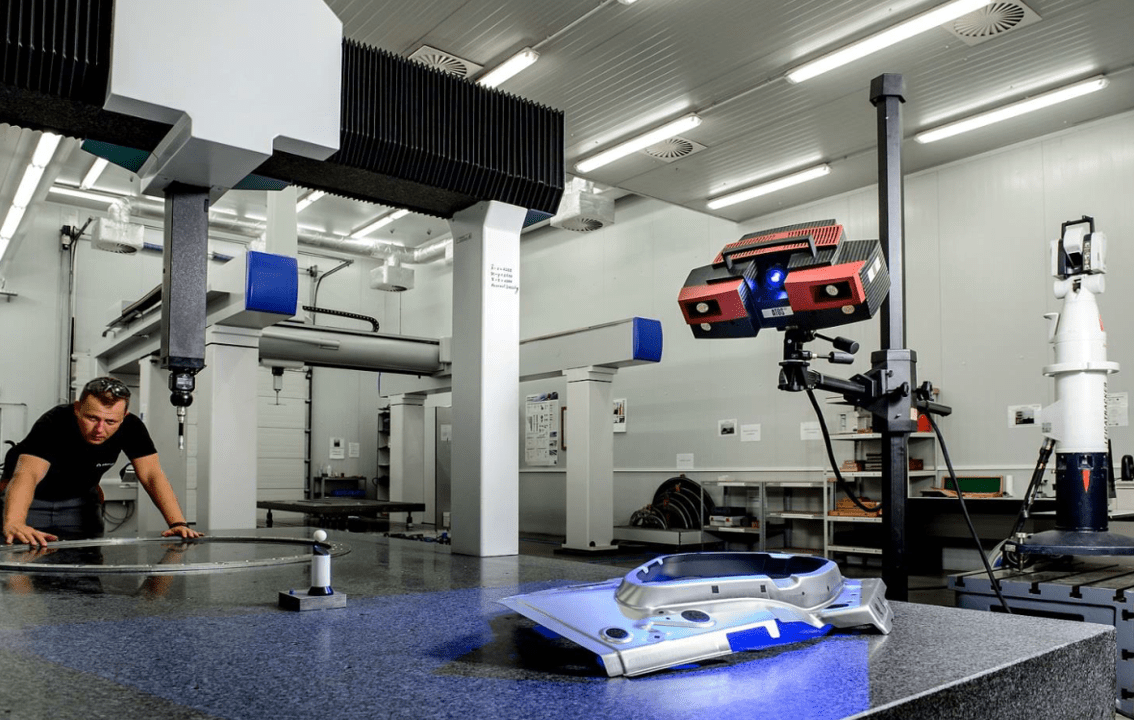

Modern milling, drilling and turning machines allow us to machine materials such as aluminium, steel, carbon steel, stainless steel, Inconel, cobalt, copper, brass or plastic. To ensure the highest precision of the machined components, we regularly perform laser inspections of the machines and their tools. This ensures that every project is carried out with top precision and fulfils your requirements.

More information

We ensure the quality of machining and supervise the entire production process. We also guarantee high standards of production and machining through quality control.

More information

We use both manual and fully automated welding to join materials. In the field of manual welding, we use conventional MIG, MAG and TIG welding methods. Our team of highly skilled EU-certified welders are capable of joining various shapes of material weighing up to 20 tonnes.

More information

Our engineering office uses CATIA, INVENTOR 2015 and EPLAN to create accurate documentation and analysis before production begins. In this way, we ensure the highest level of production efficiency, saving our customers time and resources.

More information