Our companies

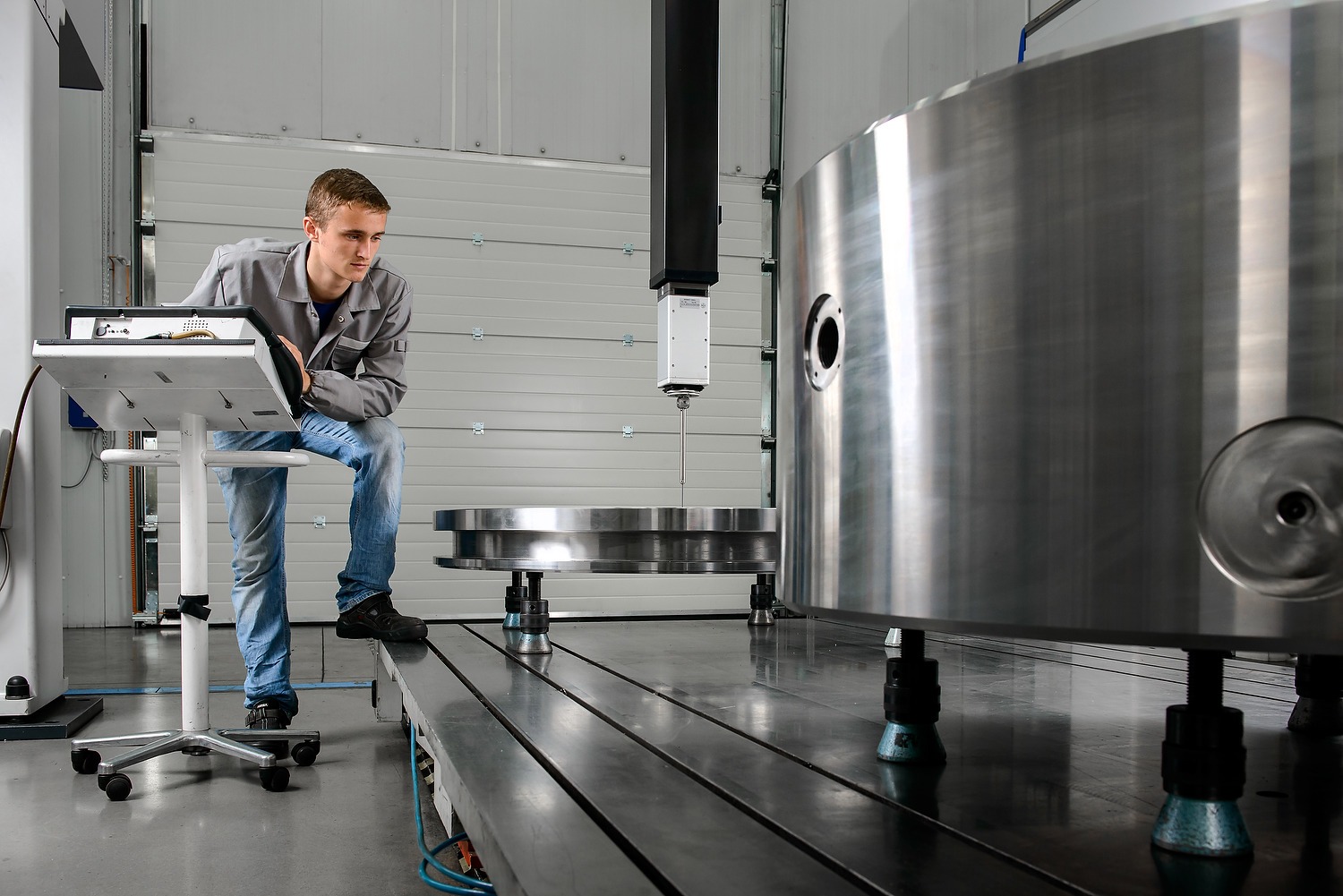

Progressive inspection methods consist of three types of 3D measurement – touch, laser and scanning. We use them throughout the entire production process to ensure the highest quality and accuracy. Our quality control teams work with the latest equipment, all of which are portable and can measure products up to 15 metres long and weighing up to 30 tonnes. The versatility and flexibility of these measurement methods offer a solid basis for the inspection and measurement of even the most complex assemblies.