Our companies

Trends in the automotive industry are constantly changing. Our Industrial Automation Division fully understands and identifies with them. That is why we can offer the best solutions for every project. Thanks to our extensive know-how, technological competence as well as the broad scope of our portfolio, we are ready to turn your ideas into personalized solutions.

We rely on our planning and analytical processes to deliver these services. In the first phase, we apply our experience to develop sophisticated planning to maximize added value for our customers. We implement the latest technologies, different brands of robots and deliver cost-effective solutions based on your requirements.

More information

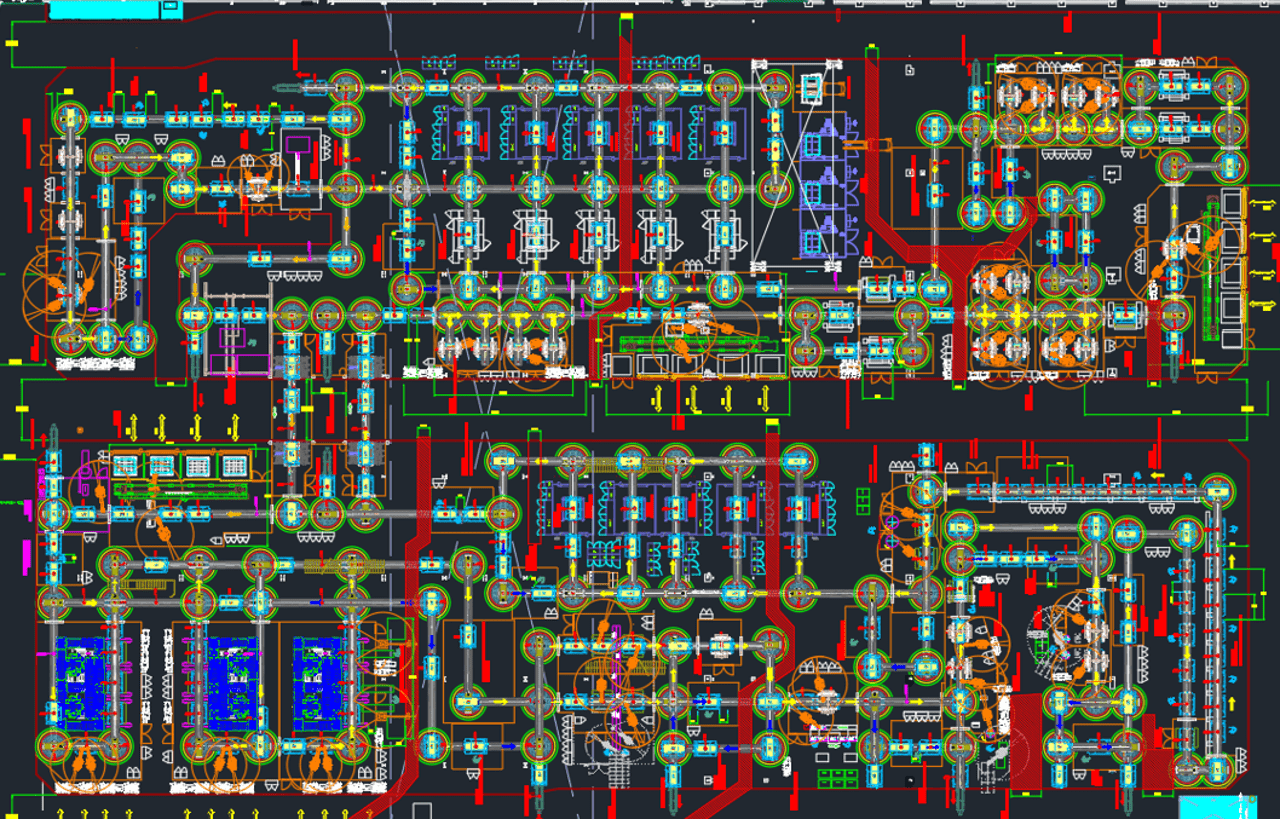

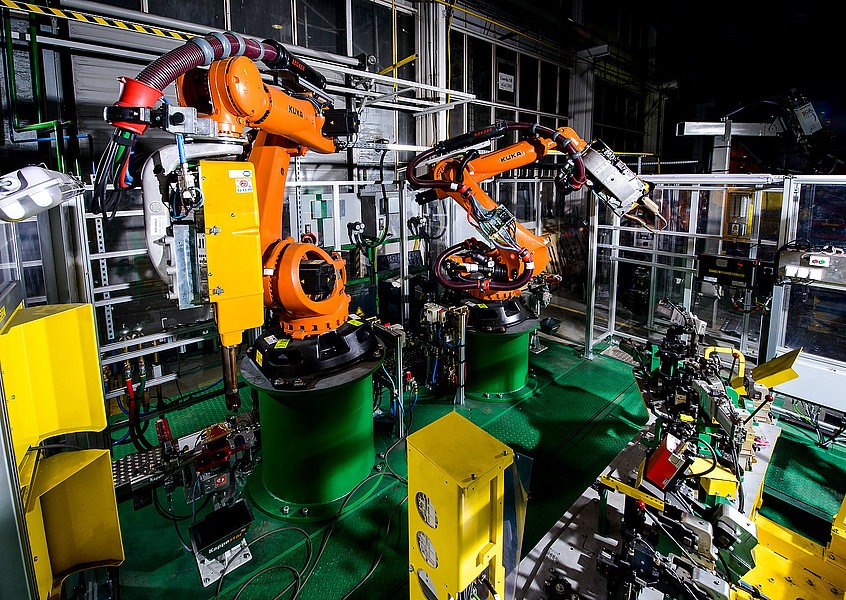

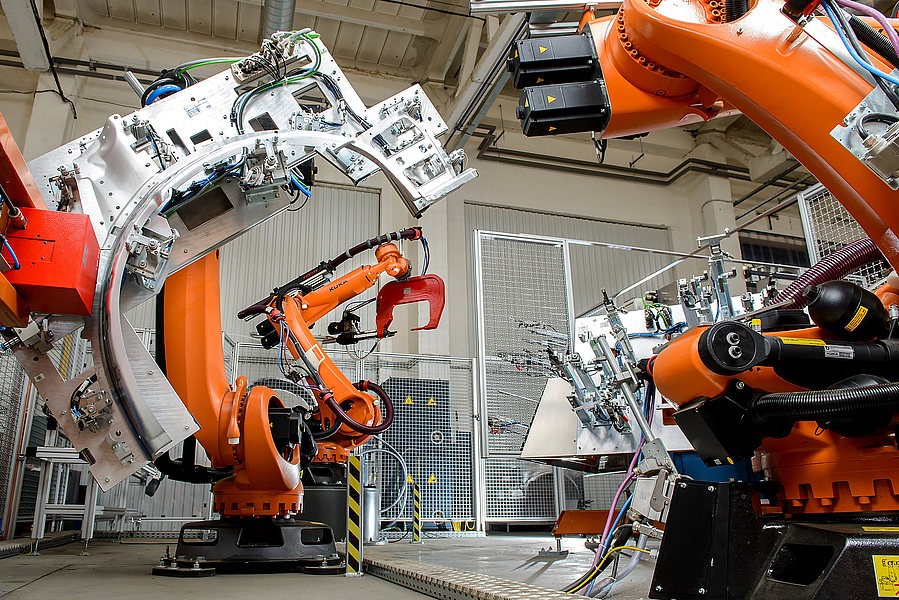

Design and line design in industrial automation. These are projects in the field of production and assembly lines, robotic workstations and lines with different ways of joining Body in White (BIW).

More information

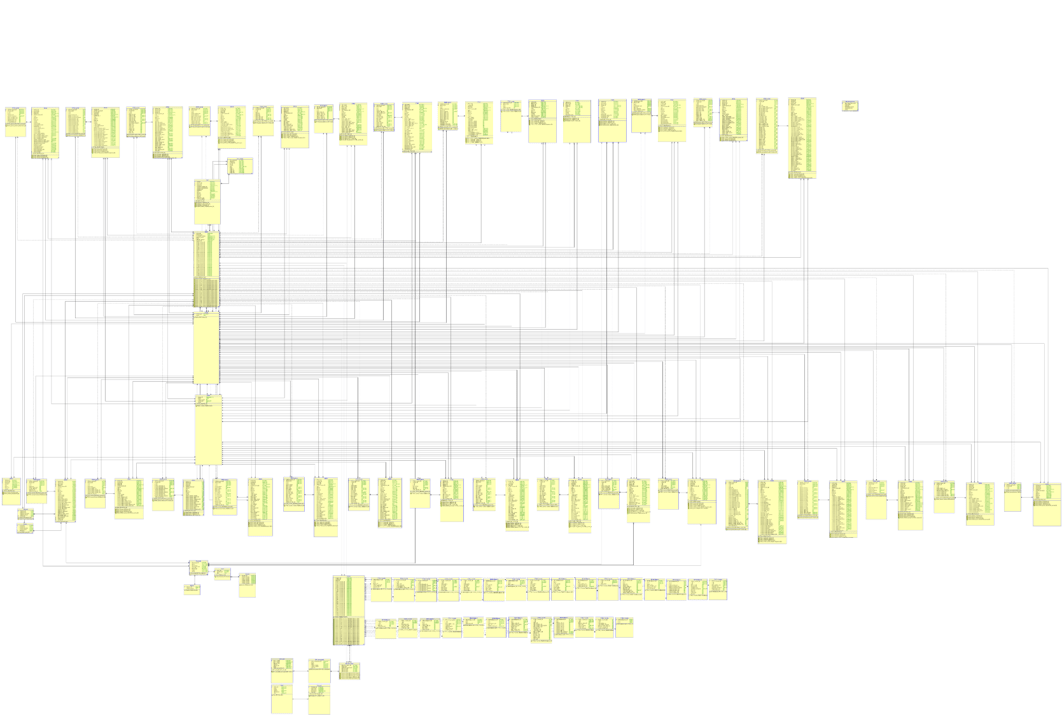

Complex systems architecture using software tools. Big Data collection, processing and analysis. Creation of databases, and interconnection of higher-level systems with production systems. Creation of applications for production and development companies.

More information

The department is involved in customer projects of industrial automation, especially projects of production and assembly lines with maximum use of robotics and automatic manipulation.

More information

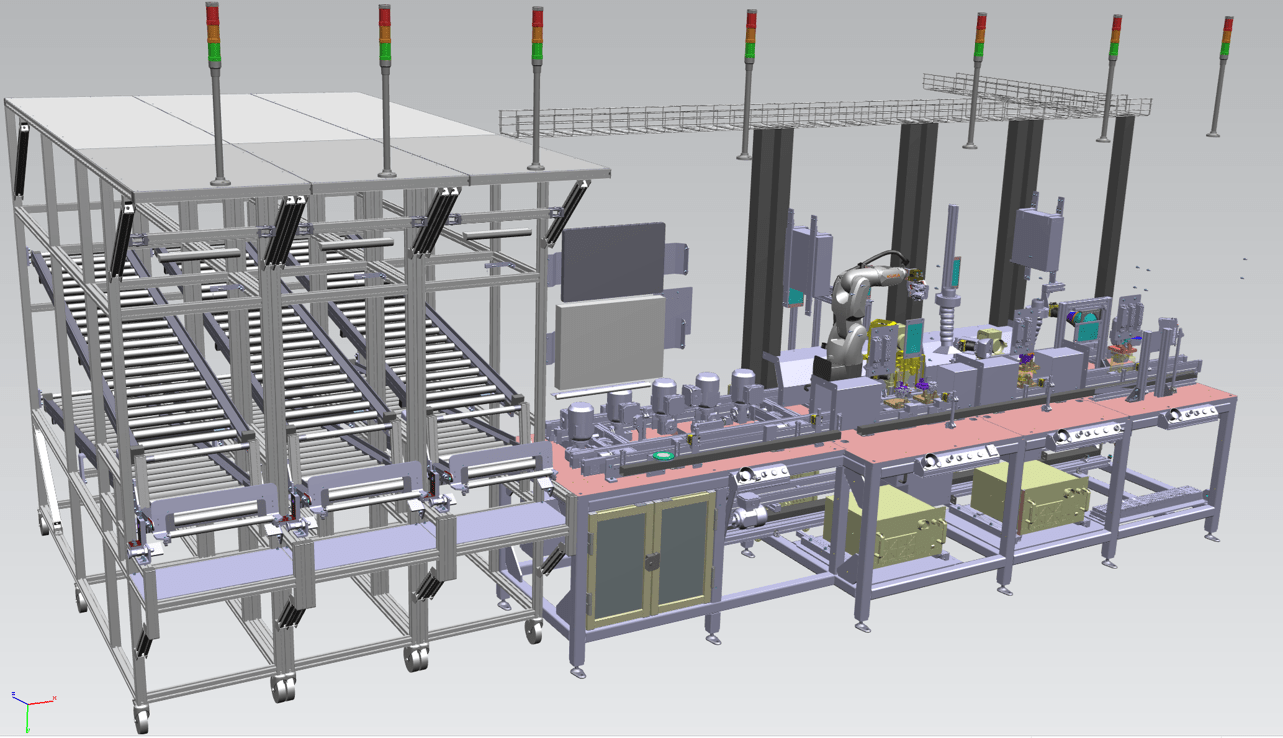

MATADOR Automation provides design and process optimization of automated lines using digital factory tools. Using virtual testing verifies conflict situations and proposes optimal solutions. We ensure that cycle times are achieved and reduced. We create robot trajectories and prepare offline programs to reduce the actual project execution time.

More information

After a phase of precise planning and engineering, we are ready for the last phase - implementation. This is where all your initial ideas materialise and take their final form. The assembly team is ready to assemble the production lines at our premises and deliver them to the job site, or build and bring them to life on your premises. Our main goal is to deliver solutions that help our customers gain a competitive advantage. Through a complete warranty and after-sales service, we provide you with impeccable care throughout the entire process of getting your line up and running, as well as the post-implementation phase. In this way, we guarantee your satisfaction and guarantee trouble-free operation.

More information

Development and integration of machine vision applications of all brands used in industrial automation. Guidance of robots by 2D and 3D camera systems, 100% quality control of products, and configuration of camera systems. Development of special applications.

More information

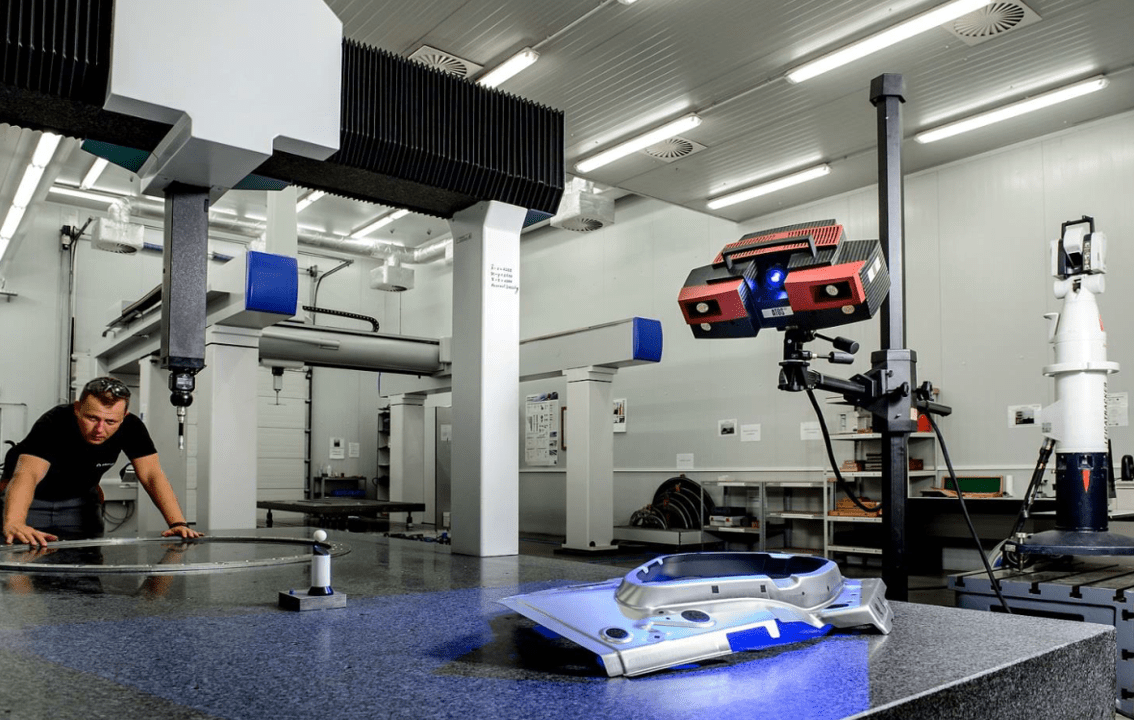

Providing contact and contactless measurement, incoming and outgoing inspection of parts, precise positioning of automatic lines, and production accompaniment.

More information

Provision of service, preventive maintenance, hotline service, remote connection, after-sales service, and spare parts.

More information

In-house development capabilities and individual departments such as conceptual planning, design, electric installation, manufacturing, assembly, programming, simulation and service enable the company to cover the entire flow of activities from design to implementation and commissioning. The presence of qualified personnel and expert technical know-how guarantees the company’s position as a Top Leader in the market.

Throughout its history, the company has become a traditional and reliable partner for many multinational companies, enabling them to move to the next level and streamline their production and logistics processes.

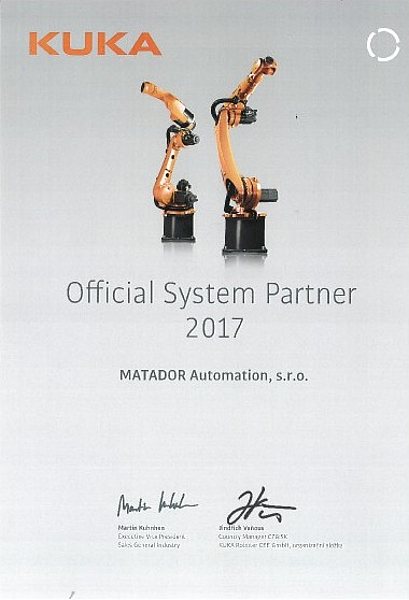

Our passion for the industry is our greatest motivator. We challenge ourselves to be better, faster, and more innovative and we set our goals accordingly. Via this approach, we move forward and constantly develop our competencies. These efforts have been recognized by KUKA Roboter CEE GmbH in 2007 when we were granted the status of an Official System Partner. Via continuous development of know-how and technological capabilities, we excelled in deliveries for our clients and further developed our competencies. In the year 2014, we became an Official Integrator for the Czech Republic and Slovakia for the first industrial collaborative robot – KUKA LBR iiwa.

completed projects

successfully integrated robots

motivated employees

The focus of operation: industrial automation: from planning, simulation and production to assembly and maintenance

Number of employees: 150+

The focus of operation: single-purpose machinery and equipment

Number of employees: 20+

Subsidiary: Alpha Automation, s.r.o.

The focus of operation: PLC programming, software and process architecture

Number of employees: 30+