MATADOR Group’s production centers in Slovakia supplying parts for 23 car models, including premium brands

Slovakia is an automotive powerhouse that produces the most cars per capita. MATADOR Group also has a significant share in this production, mainly thanks to two production plants in Vráble and Nitra. Serial parts are produced there, which are delivered not only to Slovak production plants but also to the Czech Republic, Hungary and Germany. Naturally, everything must work at a set pace, after all, all modern factories work in Just-in-Time mode.

Our production capacity clearly meets the given conditions and the portfolio of our customers is also expanding, in total we produce and supply parts for up to 23 car models! From Skoda Fabia to Lamborghini Urus. The list of models is extremely wide, it is enough to list them and it immediately becomes clear, that both Vráble and Nitra have their firm place on the global map of the world’s most important centres for the production of cars. Especially considering the number of premium brands for which we supply as well.

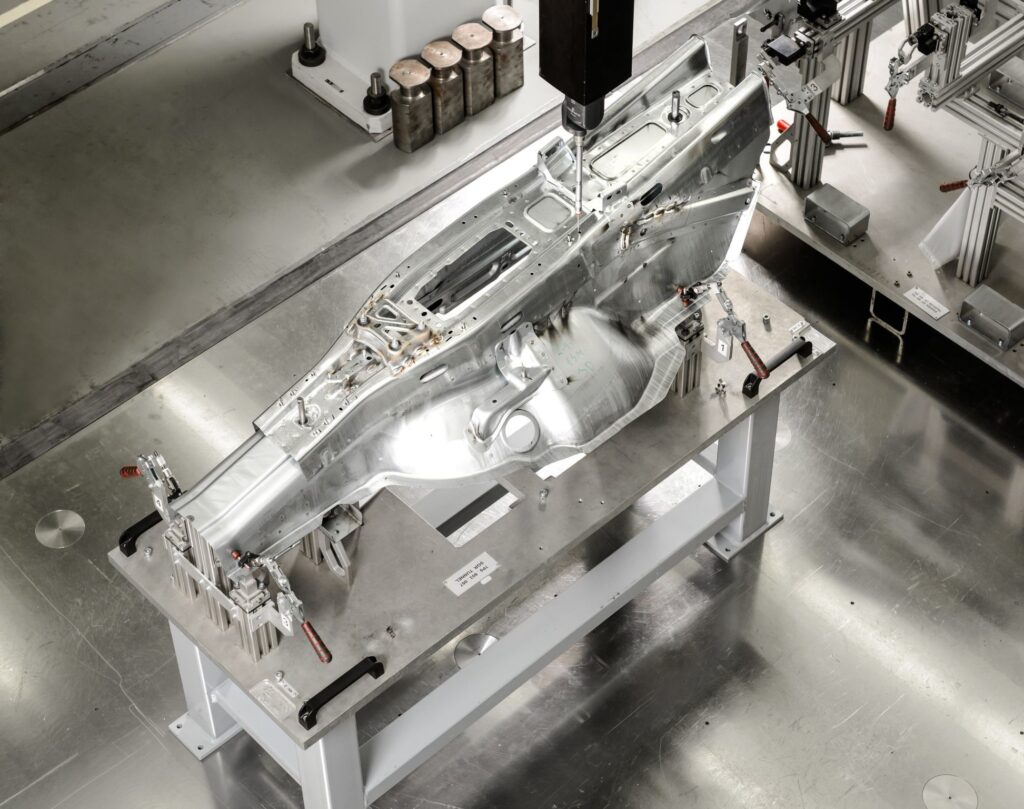

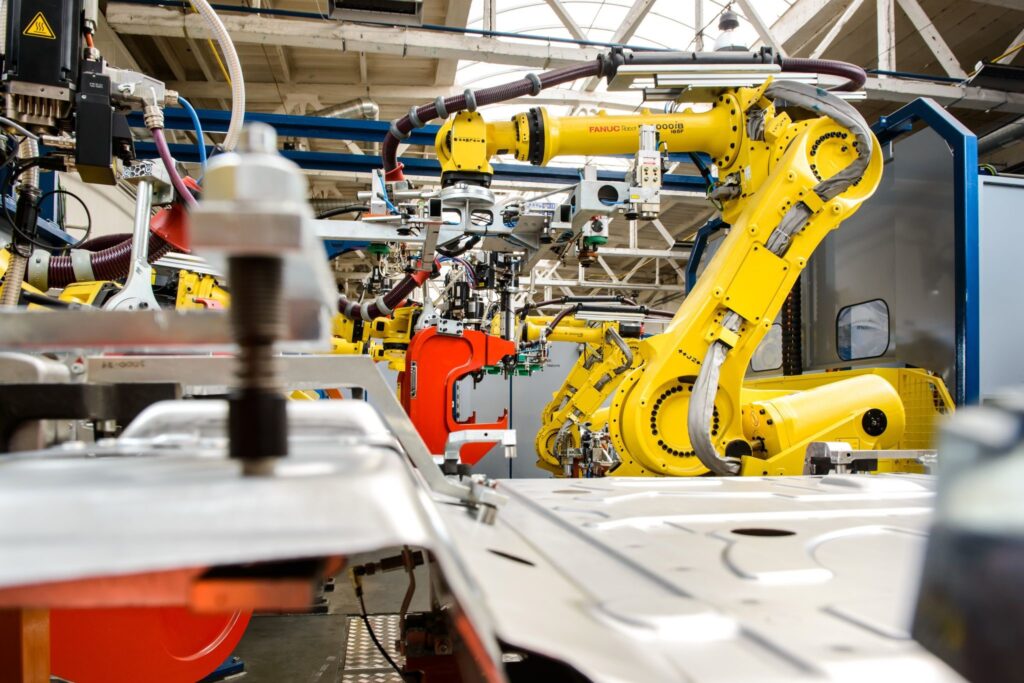

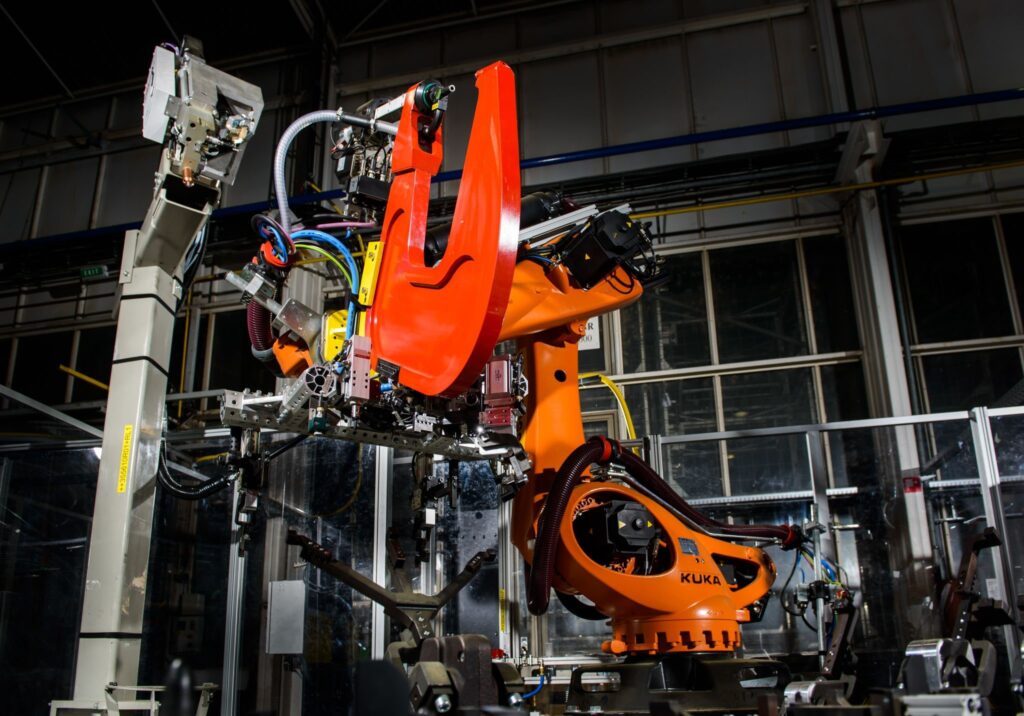

As for the types of parts, the portfolio is diverse, our production capacity focuses mainly on the so-called structural parts, which are not visible and make up the body itself or as the car terminology suggests – Body in White. From a structural point of view, these parts provide the most important parameter – the rigidity of the body. Therefore the quality and material of the individual parts are extremely important. Materials such as aluminum or thin-walled high-strength low alloy steel help to achieve a higher strength of the body without the need for an increase in weight. The extrusions must therefore be precise so that the welding robot can subsequently weld them on the line without any problems. As far as the production technique is concerned, it is mainly pressed, welded or glued.